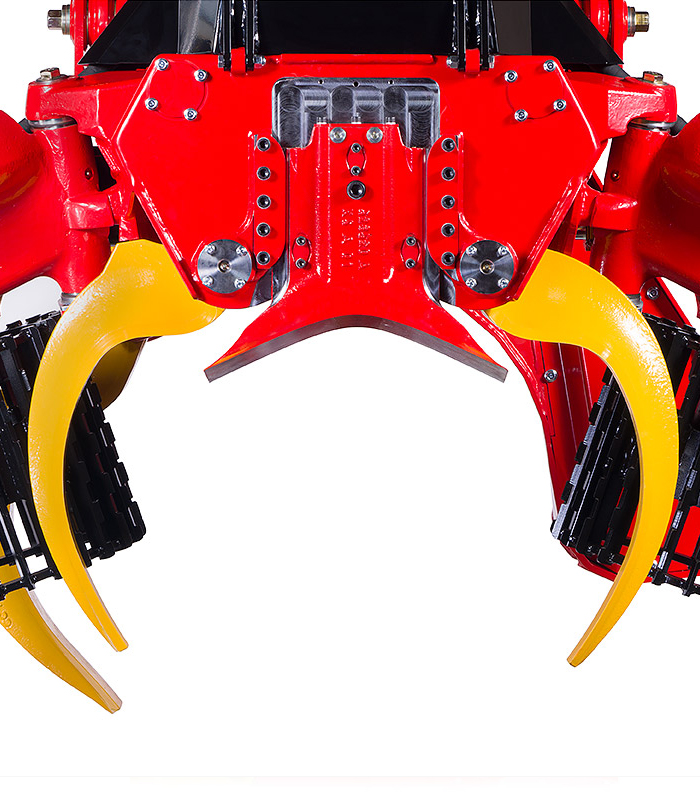

Knife Design

The delimbing knives are cast in high-strength steel and equipped with long cutting edges. This means that the limbs are cut off instead of being broken off. This minimizes friction during delimbing and allows the trunk to be fed through easily.

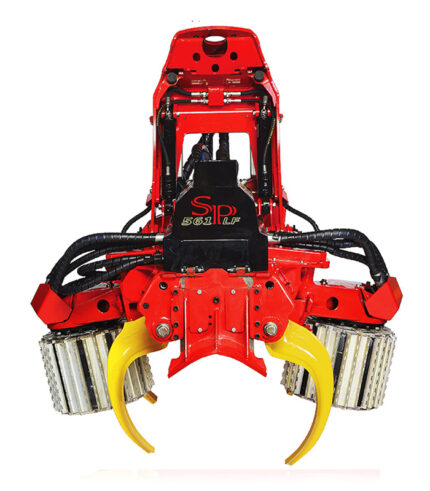

Feed rollers:

This smart solution means that when the harvester head is fully open, i.e. at maximum tree size, the feed rollers are at their greatest angle and provide maximum carrying force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction and the harvester head can feed the trunk through quickly and easily..

Proportional pressure

Proportional pressure ensures that the harvester head automatically works at the correct pressure in relation to tree diameter. This means that the friction between the trunk and harvester head is minimized and that the harvester head run at peak efficiency. Individual settings per tree species maximises production further.

LogHold

LogHold is an evolution of proportional pressure and means that the delimbing knife pressure against the trunk can be reduced, without the risk of the trunk being dropped. If the trunk is about to fall, LogHold regulates the knife pressure so that the trunk is held in the right position. The amount by which the diameter may increase before LogHold takes action is set in the control system. No additional sensors are required.

1480 kg

70 cm

16-51cm

26-30 MPa

| Hydraulic system | |

|---|---|

| Min. pump capacity | 360 l/min |

| Rec. working pressure | 26-30 MPa |

| Feeding | |

|---|---|

| Roller motors | 613-920 cc |

| Max. opening | 630 mm |

| Feed speed | 0-7 m/s |

| Feeding force | 38 kN |

| Proportional pressure | Yes |

| Cutting | |

|---|---|

| Cutting diameter | 700 mm |

| Chain speed | 40 m/s |

| Saw motor | 32 cc |

| Saw unit | SuperCut 150 |

| Tow sawing (option) | |

|---|---|

| Cutting diameter | 350 mm |

| Chain speed | 40 m/s |

| Saw motor | 20 cc |

| Delimbing | |

|---|---|

| Movable knives | 4 |

| Fixed knives | 1 |

| Delimbing diameter tip to tip | 510 mm |

| Min. delimbing diameter | 30 mm |

| Proportional pressure | Yes |

| LogHold | Yes |

| Weight and dimensions | |

|---|---|

| Width closed | 1360 mm |

| Width open | 1820 mm |

| Height, excl. tilt frame | 1730 mm |

| Weight, excl. rotator | 1480 kg |

| Weight with top saw, excl. rotator | 1595 kg |

Extra equipment

• Color marking: Used to optimize forwarding work when the assortments are difficult to distinguish by sight alone.

• Multi-tree handling: Optional equipment for heightened production when working with small-diameter stands as SP’s multi-tree handling enables you to fell and accumulate several stems to be processed together.

• Find end function: With the aid of a sensor mounted in the saw unit housing, the head automatically locates the end of the stem at the push of a button.

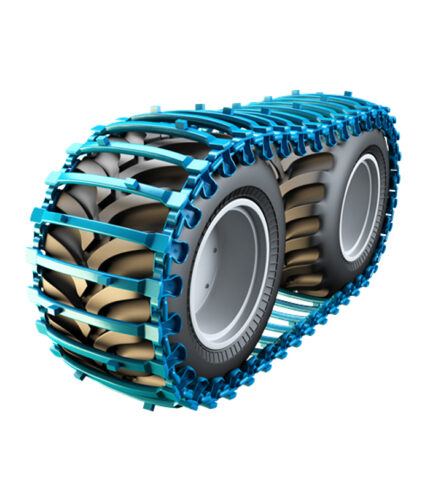

• Roller motors: Different size roller motors are available to optimize the head’s performance depending on working conditions and base machine size. Choose between two fixed displacements, 750 cc and 820 cc, and the multi-speed feed presented below.

• Light for saw unit housing: An LED lamp in the saw unit housing offers additional illumination of the work area.

• Eucalyptus kit: Debarking kit for eucalyptus trees.

• Measuring system integration: SP harvester heads can be used together with essentially any measuring system on the market. This means lower investment costs and a quicker startup as the operator need not learn a new system.

• Dasa5 complete measuring system: A complete measuring system is required if mounting the head on, say, an excavator or a tracked harvester.

• Feed rollers Several different feed roller models and variants are available to suit different conditions and needs.